- Home Page

- Company Profile

-

Our Products

- Non-woven Bag Making Machines

- B700 Non Woven Bag Making Machine

- Non Woven Box Bags Making Machines

- C700 D Cut Bag Machine

- ONLXC700 Non Woven Bag Making Machine with Online handle Attachment

- Leader Box Bag Making Machine with Online Handle Attach

- D-500 Non Woven Bag making Machine

- ONLXB700 Non Woven Bag Making Machine with Online Handle Attachment

- G700 Handle Sealing Machine

- Leader16 Box Bag Making Machine with Cooling Box Bag Function

- Non Woven Bag Making Machine with Double Line

- Auto Punching Machine

- Needle Felting Machine

- Paper Bag Making Machines

- Non Woven Offset Printing Machine

- Flexo Printing Machines

- Paper Molding Machines

- Screen Printing Machines

- Non-woven Bag Making Machines

- Contact Us

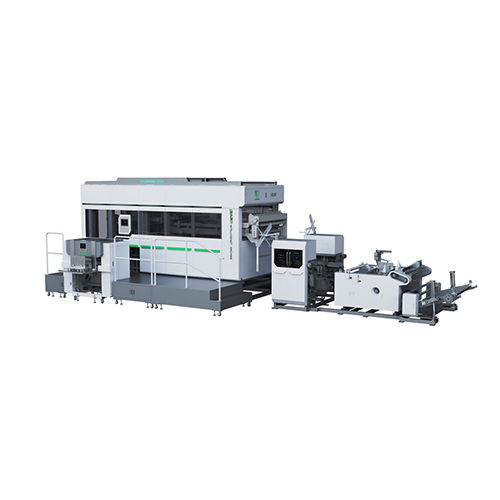

Paper Bag Making Machine

Product Details:

- Product Type Paper Bag Making Machine

- General Use Bag Making

- Click to view more

X

Paper Bag Making Machine Price And Quantity

- 1 Unit

Paper Bag Making Machine Product Specifications

- Bag Making

- Paper Bag Making Machine

Product Description

Oyang 16B330 paper bag making machine is used to produce environment friendly paper bags food paper bags and shopping paper bags with paper as raw materials This machine is to finish the paper bag by side gluing tube forming tube cutting the bottom indenting the bottom gluing bottom forming and finishing bag collection The whole machine adopts a Japanese YASKAWA electronic control system controlled by servo motor produced paper bag products high accuracy strong stability simple maintenance production efficiency is the most ideal equipment for printing plants and paper bag manufacturers

Bag Suitable

Food bag leisure food bag baking bag nuts fried bag subsidiary food bag fruit bag baby products bag etc

Bag Suitable

Food bag leisure food bag baking bag nuts fried bag subsidiary food bag fruit bag baby products bag etc

Specification

| Model | OYANG 16- B330 |

| Paper bag length (Cutting length) | 280 -530mm |

| Paper bag width | 150 -330mm |

| Paper bag bottom width | 70-180mm |

| Paper thickness | 60 -150g/m2 |

| Paper roll width | 470 -1050mm |

| Roll paper diameter | 1300mm |

| Machine MAX Speed | 220pcs/min |

| Paper bag speed | 180-200pcs/min |

| Machine power | 380V 3 Phase 4 line 8kw |

| Machine weight | 8000kg |

| Machine size | 9500x2600x1900mm |

BOTTOM FOLDING METHOD

- W : paper bag width

- C : paper bag tube length

- L : paper bag height

- H : paper bag bottom width

Description And Configuration Of Main Stricture And Function

Paper Material Feeding System

1 The Feeding Is Equipped With An Automatic Lifting Function The Main Function Is Easy To Replace The Paper During Production Can Be Easily Completed Through The Switch Control

Unwinding Using Air Expansion Axis

Feeding Is Equipped With Hydraulic Cylinder Lifting Control System

Feeding With Automatic Tension Control System

2 Automatic Stroke Correction System The System Is Mainly To Ensure The Smoothness And Stability Of Web Paper Feeding State

- Unwinding unit : 1 SET

- Pneumatic brake : 1 SET

- Auto tension : 1SET

- Auto EPC system (PAUSOURCE) : 1SET

- Auto stop system

Paper Bag Bottom Forming System

- Traction system servo motor (YASKAWA JAPAN): 1 SET

- Main servo motor (YASKAWA JAPAN) : 1SET

- Traction roller : 2SET

- Bag length cutting unit : 1SET

- Bag conveyor unit : 1 SET

- Bag bottom creasing unit : 1 SET

- bag bottom open unit : 1SET

- Bottom glue unit : 1SET

- Bag bottom close unit : 1 SET

- Bag collection unit : 1 SET

- Lubricating oil system (China) :1 SET

- Cylinder (DELIXI)

- Pneumatic valve (DELIXI)

- Paper checking sensor (Panasonic JAPAN)

- Bearing Germany NEY

Multi Layer Bottom Forming Drum Center Grippers Second Tuck Clamps and Drum Fingers are adjustable for ease of changeover

Paper Bag Collection System

The formed paper bag is pressed together and conveyed out. The bag collection device can set automatic counting when the finished product is out of the bag according to the requirements.

- Vertical bag collection unit : 1 SET

- Working table : 1 SET

- Auto Counting system : 1 SET

Eletric Configuration

- Motion Controller : (YASKAWA Japan) 1set

- Ethernet Full Color Touch Screen : (FLEXEM 1set

- Servo Drive : (YASKAWA Japan) 2set

- Input And Output Pnp (YASKAWA Japan):1set

- Power And Feedback Cable: (MITSUBUSHI Japan) 1set

- Circuit Breaker : (SHNEIDER France)

- Contactor : (SHNEIDER France)

- Relay (SHNEIDER France)

Main Machine Material And Processing Technic

- Main wallboard material : nodular cast iron QT400

- Gear material : 38CrMnAl

- Shaft material : 45 40Cr

- Other materials : ZG270-500, G12MOV

- The thickness of the shaft plating layer : 0.08mm

- The surface hardness of the gear : 45-50HRC

- Conveyor belt material : Switzerland Habasit

Enter Buying Requirement Details